In modern office and industrial manufacturing, the printer is one of the indispensable tools, and the quality of its output directly affects work efficiency and brand image. However, many people tend to overlook a key role-the print ribbon. As an important consumable hidden behind the scenes, high-quality print ribbon can significantly improve the clarity, durability and consistency of documents or labels.

So what kind of print ribbon can be called "high quality"? The answer lies in many aspects. First of all, the choice of materials is crucial. Only the selection of environmental protection ink raw materials after strict screening, in order to ensure that the image lasting bright and not easy to fade. Secondly, advanced production technology is also an indispensable part. This not only involves the application of precision coating technology, but also how to ensure that every millimeter of each roll of ribbon is evenly distributed with sufficient dye content.

Compatibility is also an important indicator. No matter what type of paper media or complex printing task requirements, a truly excellent printing ribbon should be seamless, reducing the probability of paper jams and extending its service life.

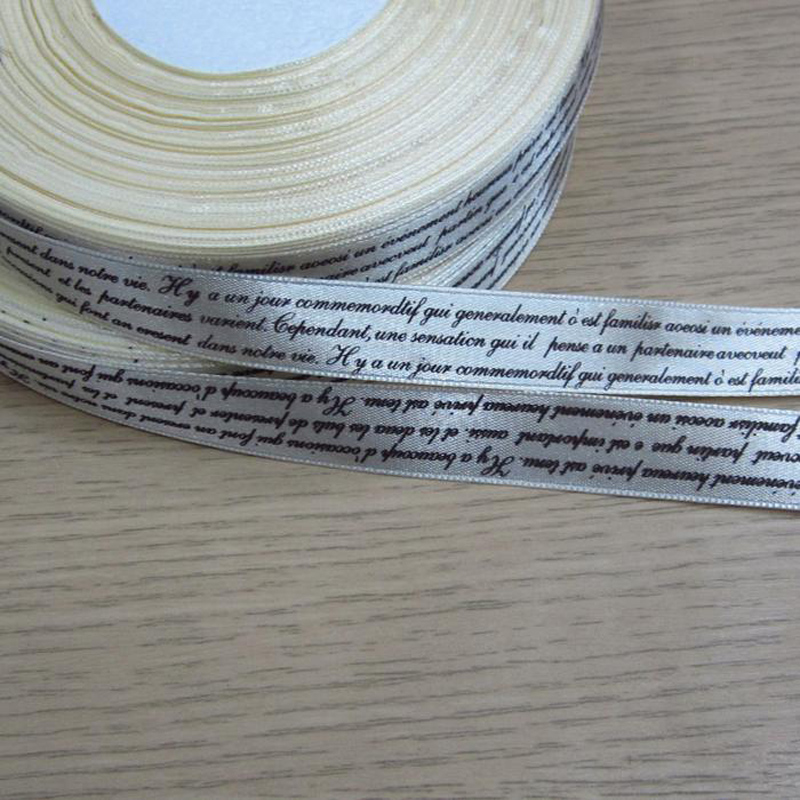

Of course, in today's increasing personalized demand, "standardized" products obviously cannot meet the requirements of all customers. That's why we 've launched a custom print ribbon service designed to create a world of color for our customers. Whether it is the need to adapt to the UV resistance characteristics of special application scenarios or the pursuit of a distinctive design style, our team can flexibly adjust the formulation parameters to achieve these unique demands.

In order to make every user feel the convenience brought by this exclusive customization, we also provide a free sample application option. From the initial conceptual communication to the final delivery of the finished product, every link has been carefully polished to ensure that the quality of service is always on the line at a high level. For example, after receiving the customer's demand, professional and technical personnel will conduct a comprehensive evaluation and then formulate a detailed implementation plan. Then, during the proofing phase, the other party will be invited to participate in the actual test so as to find problems in time and make corresponding improvement measures until satisfactory results are achieved.

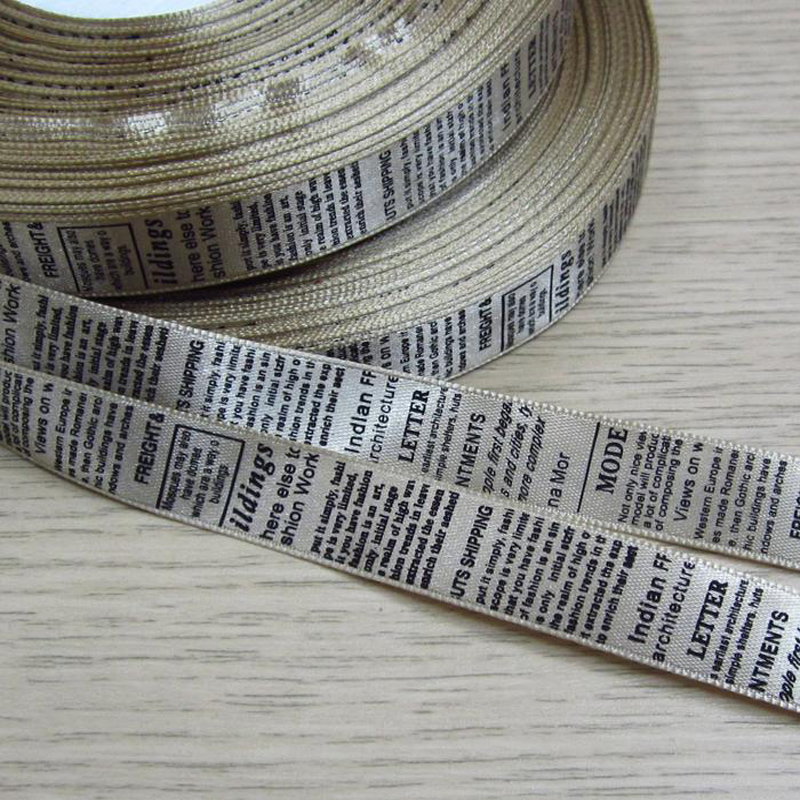

In fact, many businesses have benefited from this service. For example, a logistics company encountered the problem that the traditional black characters are easy to blur when upgrading the packing box identification system. By selecting the gold special printing ribbon with metallic luster effect, the problem that has plagued for many years has been solved, and the efficiency of transportation information identification has been greatly improved, thus reducing the operating cost.

Looking to the future, with the continuous development of artificial intelligence and Internet of Things technology, it is expected that intelligent printing will become one of the mainstream trends. At that time, it will not only be possible to remotely monitor the operating status of the equipment, but also to automatically replenish the inventory of relevant accessories, thus completely liberating the human burden and allowing more time to be devoted to more creative work.

In short, whether it is today or in the future, having a set of high-quality printing solutions suitable for your business characteristics will inject strong motivation for the long-term development of enterprises.