The era of customization is coming | Why do you say that printing ribbons also need exclusive personality design?

in this era of pursuit of unique expression, whether it is corporate logo management or personal work presentation, the same standard scheme has long been unable to meet the increasingly subdivided demand scenarios. Especially in industrial manufacturing, retail packaging and special purpose fields, accurate marking information is not only related to brand image, but also directly affects work efficiency and customer experience.

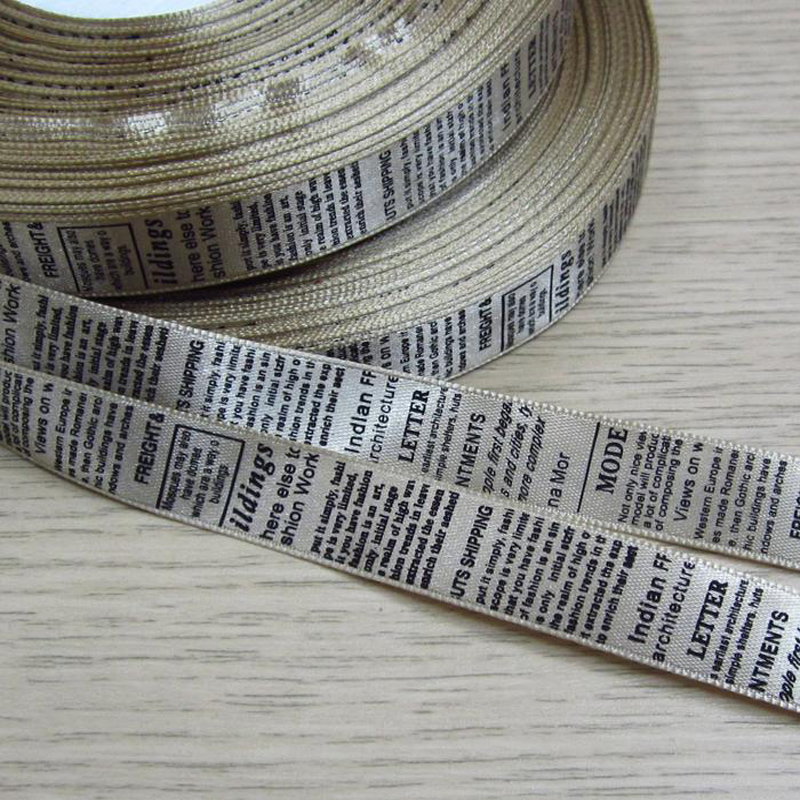

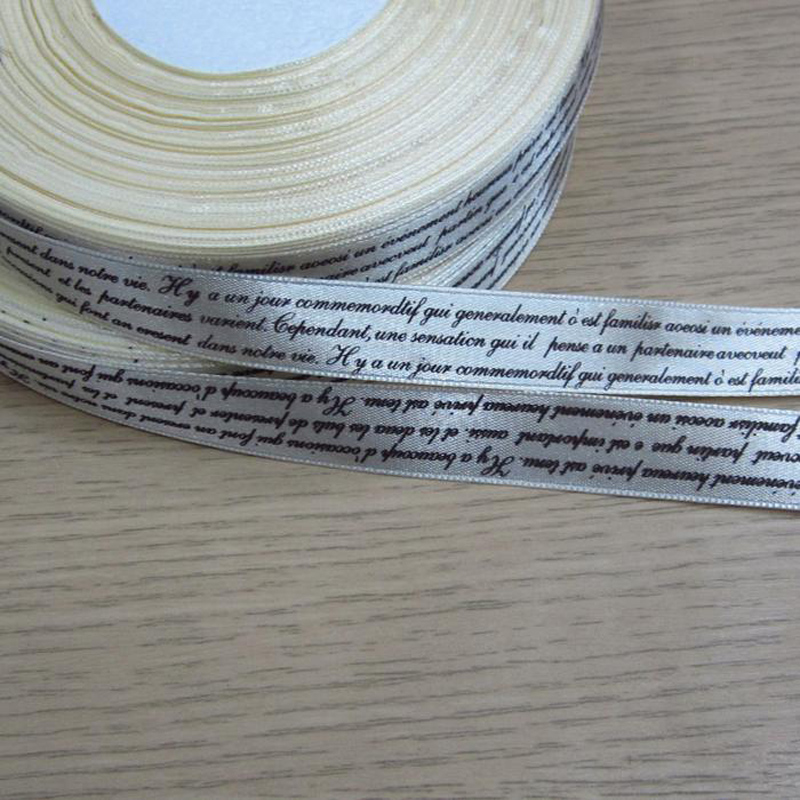

This is where our custom print ribbon was born-rejecting template duplication and tailoring every color to your business. From size specifications to pattern texture, to text typesetting and even color gradient transition effect, can be defined freely according to customer needs, truly different.

to find out | analysis of core materials and process highlights of high quality printing ribbon

The professional-grade thermal transfer composite substrate imported from Europe is selected as the carrier, and the surface hardness and oxidation resistance are greatly improved under the premise of ensuring flexibility and ductility. Even in the face of high temperature and humidity, the harsh conditions are still timeless.

at the same time, the special ink formula developed in germany is adopted, which makes the finished product have excellent adhesion and sharpness of development. no matter the line outline or the large filling block, it is delicate and clear without defects, making every output as delicate and moving as a work of art.

Flexible matching and worry-free use | Technical adaptation tips behind multi-model device compatibility

in order to break the limitation barrier that traditional consumables can only be used in a single model, we started to study the internal structure of mainstream printers of major famous brands in the world at the beginning of product development, and adjusted the key parameters such as reel diameter ratio, induction hole position distribution and even the overall thickness tolerance range.

this series of elaborate improvement measures have finally achieved surprising results: it can run smoothly on most desktop and commercial-grade labeling machines with simple installation steps, completely bid farewell to the troubles caused by frequent replacement of accessories, and truly achieve plug and play and control freely.

from concept to reality | detailed explanation of the sample customization process will lead you to understand each step of change intuitively

when you submit the preliminary idea, the senior graphic designer team will take the initiative to contact and closely communicate with them in the first time to reach a consensus on the details of the design concept until a consensus is reached. Then enter the sample trial stage to check whether all indicators meet the standards on the spot.

after confirming satisfaction, it will be officially put into mass production line. the whole process will be implemented in a fully enclosed dust-free workshop control system, and multiple quality inspection barriers will be added to strictly control the quality defense line, so as to minimize the error and only deliver the long-awaited ideal result.

Practical Cases | What trends do successful applications in these industries prove?

an electronic product manufacturer hopes to improve the accuracy of the production line traceability system through the new bar code, but suffers from the fact that ordinary toner is easily blurred by wiping, resulting in frequent scanning failures. With the help of our high-strength anti-scratch printing ribbon solution, the number of failures has been greatly reduced by more than 90%.

another large supermarket chain uses repeatable versions to complete the dynamic update of shelf numbers. compared with the previous consumption of hundreds of paper stickers per month, it not only saves costs but also conforms to the green environmental protection proposition, thus forming a sharp contrast to the win-win situation.

Beyond Basic Features | Additional Process Options Give More Additional Possibilities to Explore Space

in addition to the regular of black and white and monochrome systems, it can be further upgraded to add waterproof and fire protection grade enhancement processing procedures to make it more suitable for long-term service without failure and damage in outdoor outdoor occasions or working environments with chemical corrosion risks.

in addition, there is a luminous reflective coating to choose from, which instantly reflects eye-catching light under strong light at night to play a significant warning role. it is very suitable for application in safety indicator production projects to play unexpected good results.

the future has come forward-looking layout | how to view the development trend of printing consumables driven by intelligence?

With the advent of the Internet of Things IoT era, the future of printing consumables is not just a simple and crude process of passively accepting instructions and executing commands. Instead, they should become an integral part of the entire ecosystem and participate in the data interaction process.

imagine if you can automatically push to remind the administrator when the remaining amount is insufficient, the APP interface on the mobile phone will display the real-time inventory status and download the latest firmware file remotely through the cloud server to optimize the settings by yourself... all this is not an unreachable dream but a beautiful reality within reach.